How Epoxy Molding Compounds (EMC) Are Transforming Semiconductor Packaging in Europe’s Booming Tech Industry

“The European Epoxy Molding Compounds (EMC) market for semiconductors is growing steadily. This growth is driven by the increasing demand for advanced IC packaging and the rise of electric vehicles and 5G technology.

Factors like investments in semiconductor facilities and the shift toward sustainable packaging are boosting demand. While challenges such as supply chain issues and regulatory pressures exist, partnerships between semiconductor firms and EMC manufacturers are likely to foster innovation in the industry. "

The Europe Epoxy Molding Compound in Semiconductor Packaging market was valued at USD 479 Million in 2024 and is projected to reach USD 892 Million by 2032, with a compound annual growth rate (CAGR) of 7.5% from 2025 to 2032.

Additionally, strict environmental regulations that promote halogen-free and low-VOC (volatile organic compound) materials are encouraging innovation and investment in sustainable EMC solutions. The presence of major semiconductor manufacturers and packaging service providers in countries such as Germany, France, and the Netherlands further supports market expansion.

The European Union's initiative to reduce dependency on Asian semiconductor supply chains, exemplified by the EU Chips Act, is also driving local production and research and development investments in advanced packaging technologies. Together, these factors make Europe the fastest-growing region in the global EMC semiconductor packaging market.

The demand for EMC in packaging is rising as a result of government-backed investments in Europe's semiconductor production.

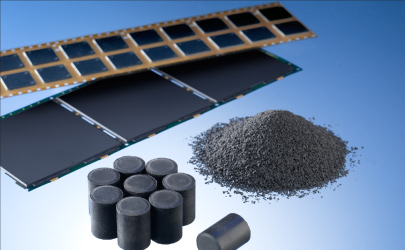

Europe is making significant strides in expanding its semiconductor manufacturing capabilities, driven by substantial government initiatives and private investments. The European Chips Act, introduced by the European Union, aims to strengthen the region’s semiconductor supply chain by increasing the EU’s share in global semiconductor production from 10% to 20% by 2030. This initiative has encouraged global semiconductor players to set up or expand their packaging and fabrication facilities in Europe. The rising demand for advanced semiconductor packaging technologies, including System-in-Package (SiP), Flip Chip, and Wafer-Level Packaging (WLP), has fueled the need for high-performance Epoxy Molding Compounds (EMCs). These compounds offer excellent mechanical stability, thermal resistance, and electrical insulation, making them ideal for encapsulating semiconductor components.

The rise of EVs and ADAS in Europe is driving the need for durable and heat-resistant EMC in automotive semiconductor components.

The automotive industry is a significant driver of semiconductor growth in Europe, particularly due to the rise in electric vehicles (EVs), hybrid electric vehicles (HEVs), and autonomous driving technologies. European automakers such as Volkswagen, BMW, and Mercedes-Benz are making substantial investments in vehicle electrification and advanced safety systems, resulting in an increased demand for power modules, sensors, and microcontrollers.

These components need strong protection against moisture, temperature fluctuations, and mechanical stress, which makes electromagnetic compatibility (EMC) a crucial factor in automotive semiconductor packaging. Furthermore, Advanced Driver-Assistance Systems (ADAS)—which include features like lane departure warnings, collision detection, and adaptive cruise control—depend on highly sensitive electronic components that benefit from the reliability of epoxy-based encapsulants.

The rollout of 5G and IoT technologies is accelerating the need for high-performance, miniaturized semiconductor packaging using EMC.

The rollout of 5G networks and the rapid growth of Internet of Things (IoT) applications in Europe have significantly increased the demand for high-performance semiconductor chips. Devices such as smartphones, wearables, industrial sensors, and smart home appliances require compact yet durable semiconductor packages. Electromagnetic compatibility (EMC) materials play a crucial role in enhancing chip protection, thermal stability, and electrical performance in these devices. Additionally, Europe’s emphasis on Industry 4.0, which encompasses artificial intelligence, machine learning, and edge computing, is further driving the need for advanced EMC materials in next-generation semiconductor packaging solutions.

Europe enforces strict environmental policies, encouraging the adoption of eco-friendly and halogen-free EMC solutions.

Europe is recognized for its strict environmental regulations, and the semiconductor industry is no exception. Regulatory frameworks such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) mandate the use of eco-friendly, halogen-free, and lead-free epoxy molding compounds. These regulations encourage manufacturers to create low-toxicity, recyclable, and high-performance EMC materials that align with sustainability goals. Furthermore, the European semiconductor industry is transitioning towards energy-efficient production processes and reducing hazardous waste, which drives the adoption of environmentally friendly EMCs.

Presence of Leading Semiconductor and Material Suppliers.

Europe is home to some of the world's largest semiconductor manufacturers and material suppliers, which play a crucial role in driving innovation in EMC (Electromagnetic Compatibility) technology. Companies such as Infineon Technologies, STMicroelectronics, and NXP Semiconductors are leading advancements in semiconductor packaging, contributing to the increased adoption of high-reliability EMC solutions.

Additionally, major chemical and material science companies, including BASF and Henkel, are investing in research and development to create next-generation epoxy compounds. These new materials are designed with enhanced properties, such as higher thermal conductivity, improved electrical insulation, and increased moisture resistance.

The presence of a strong ecosystem consisting of chip manufacturers, material suppliers, and research institutions provides a solid foundation for the rapid growth of the EMC market in Europe.

Competitive Landscape

Some of the major companies operating within the Epoxy Molding Compound in Semiconductor Packaging market are: Sumitomo Bakelite, Showa Denko, Eternal Materials, Chang Chun Group, Kyocera, ShinEtsu and Others.